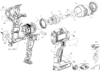

I have one of these:

and when I was screwing in (eventually try speed 2 on full torque), it didn't manage to screw in a coach bolt (75mm) into a rawl plug. I got it 3 quarters of the way home but it wouldn't go any further. I suspect my impact driver would have done it if I had it to hand...

Question: is this drill/driver designed for such a purpose? Should it have managed this?

and when I was screwing in (eventually try speed 2 on full torque), it didn't manage to screw in a coach bolt (75mm) into a rawl plug. I got it 3 quarters of the way home but it wouldn't go any further. I suspect my impact driver would have done it if I had it to hand...

Question: is this drill/driver designed for such a purpose? Should it have managed this?