Just wondering if somebody can help me set up my underfloor heating please on a house I have just bought- no manual supplied.

My control unit is "multi-zone control centre PPI-1050" manufactured by "United controls limited" who no longer exist. I cannot find a manual online.

If somebody could correct or confirm my understanding it would be much appreciated.

The above photo is what is displayed after I press "set". I assume that this is the target temperature for water feeding in to the UFH.

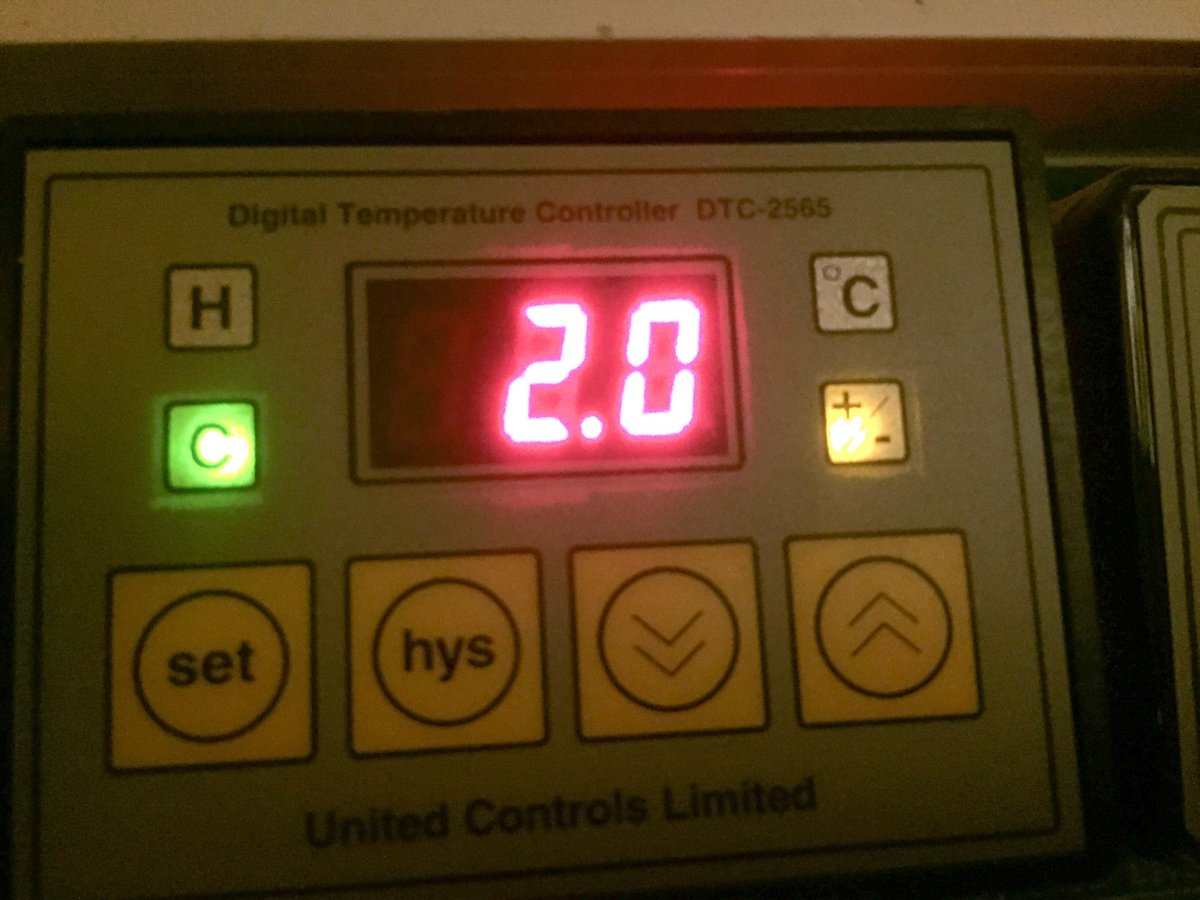

The above picture is the from the home screen, "C" is illuminated as it is on the cooling phase as the temperature is higher than the set point.

The above picture is the screen that displays after I press "hys". I understand that this means that the temperature range is 2 degrees from the set temperature i.e. 43-45 degrees.

I cannot figure out how to change these values. Is there a way of doing this??

Thanks

My control unit is "multi-zone control centre PPI-1050" manufactured by "United controls limited" who no longer exist. I cannot find a manual online.

If somebody could correct or confirm my understanding it would be much appreciated.

The above photo is what is displayed after I press "set". I assume that this is the target temperature for water feeding in to the UFH.

The above picture is the from the home screen, "C" is illuminated as it is on the cooling phase as the temperature is higher than the set point.

The above picture is the screen that displays after I press "hys". I understand that this means that the temperature range is 2 degrees from the set temperature i.e. 43-45 degrees.

I cannot figure out how to change these values. Is there a way of doing this??

Thanks