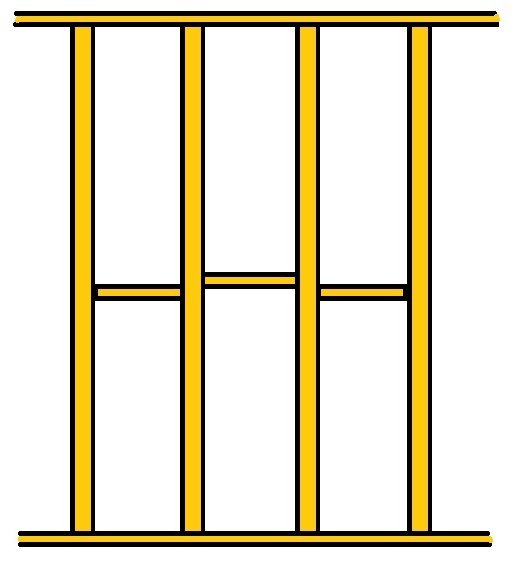

On my plans I've said that I'll have first floor and roof level joist strutting from noggins/offcuts, and I'll certainly have the wood available to do so. However, I've just discovered the existence of these metal equivalents. I'm guessing they'll make for a quicker job, but will it be a better result (other than being easier to put cables/pipes through?)

Thanks

Gary

Thanks

Gary