Seasons Greetings.

I was asked to check out my in-laws failed microwave a couple of days ago. Although only a couple of months old, it has stopped working as though it wasn't getting power.

I checked the 13amp fuse in the plug and replaced it, but no luck. I then plugged the microwave (with the original fuse re-fitted) into a different wall socket and it worked.

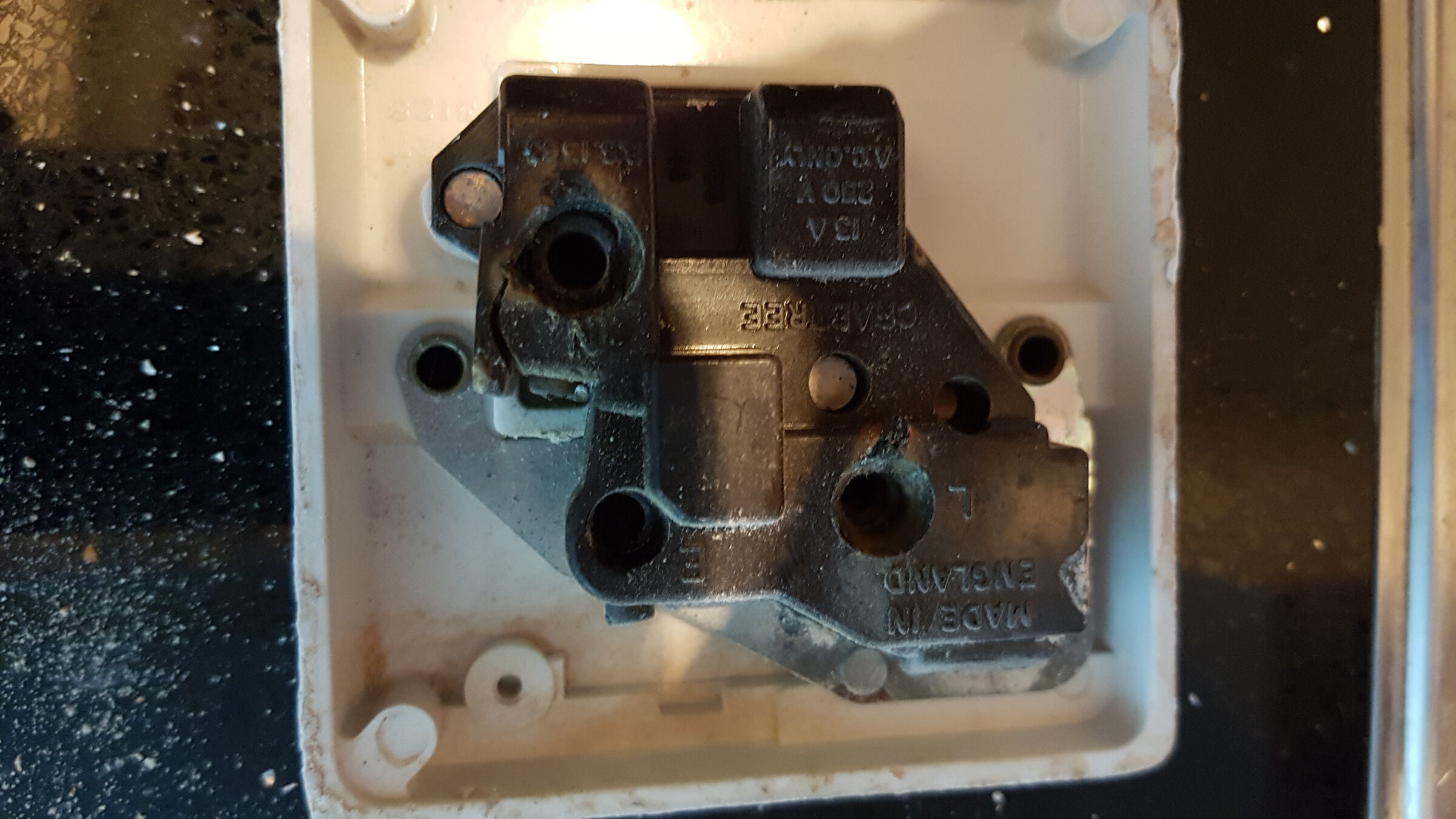

I then started to unscrew the front of the wall socket and heard a "sizzling" sound, so stopped. I located a spare single gang, switched plug socket, then isolated the power and removed the socket, so see the following:

The wire connections into the socket were solid - I had expected one of them to be loose. As you can see there's a sign of scorching on the neutral, and possibly a little on the live also. I noticed the neutral socket connection had a crack in it.

The house was built in around 1984 and as far as I know it hasn't ever been rewired, so I was a little surprised to see two types of cable, although I guess it is possible kitchen fitters may have done some wiring!

Although the new switched plug socket is working, I'm concerned about the signs of scorching on the cables.

Any idea why this might be happening? I assume this is a sign of the cable being overloaded, but could a "faulty" socket also cause this?

I was asked to check out my in-laws failed microwave a couple of days ago. Although only a couple of months old, it has stopped working as though it wasn't getting power.

I checked the 13amp fuse in the plug and replaced it, but no luck. I then plugged the microwave (with the original fuse re-fitted) into a different wall socket and it worked.

I then started to unscrew the front of the wall socket and heard a "sizzling" sound, so stopped. I located a spare single gang, switched plug socket, then isolated the power and removed the socket, so see the following:

The wire connections into the socket were solid - I had expected one of them to be loose. As you can see there's a sign of scorching on the neutral, and possibly a little on the live also. I noticed the neutral socket connection had a crack in it.

The house was built in around 1984 and as far as I know it hasn't ever been rewired, so I was a little surprised to see two types of cable, although I guess it is possible kitchen fitters may have done some wiring!

Although the new switched plug socket is working, I'm concerned about the signs of scorching on the cables.

Any idea why this might be happening? I assume this is a sign of the cable being overloaded, but could a "faulty" socket also cause this?