Hi all. I’ve just joined this forum because I have EXACTLY the same problem with the same WB boiler as GeddeMortgage has been describing and came across this discussion whilst searching on-line for information. Much of what has been said above has also been coming out of my mouth almost verbatim over recent days! I will set the scene as briefly as I can but then I do have one idea/question to raise that hasn’t been mentioned so far.

My boiler is a 30kW Greenstar 8000 Style system boiler that was installed in mid-2022. It is set to 20kW maximum output and runs central heating with about 14kW of radiators and also heats a domestic hot water cylinder. It doesn’t have an internal diverter valve but there are three external motorised valves for the hot water and two heating zones. We don’t normally heat the DHW and run the heating at the same time, so my issues relate mainly to heating operation.

Like GeddeMortgage, I was noticing that despite the boiler being set to 70C, radiators were rather cool and slow to heat the house, so I used my Bosch IR thermometer (with black tape on pipes!) to check actual flow temperature at the pipe just outside the boiler and at input to radiators; lo and behold, only 50C whilst the service menu display on the boiler was showing HEx and flow temperatures of 70C or just above. How could this be the case?!

Trying to keep the story short, my accredited installer said he had only seen this once before and replacing the boiler flow temperature sensor had made no difference. He advised me to email the details to WB Technical Support, who responded immediately purely with advice to arrange an engineer call-out, as it was probably a flow sensor fault (which I somewhat doubted given my installer's experience and the fact that the displayed HEx temperature always closely tracks the displayed flow temperature).

On arrival, the engineer agreed there was an obvious discrepancy between the display and the actual flow temperature leaving the boiler and arriving at nearby radiators. He said he had never seen the issue previously and suggested that the 20C temperature drop was occurring between the flow pipe exiting the HEx and the outside of the boiler (ridiculous, as pointed out above!) but then had to admit that the pipe exiting the HEx was no hotter. He therefore replaced the flow temperature sensor, the control panel and the control unit but with no improvement. He cast doubt on the accuracy of my IR thermometer despite this having been calibrated but I have now used three different types of thermometer, which all confirm the same.

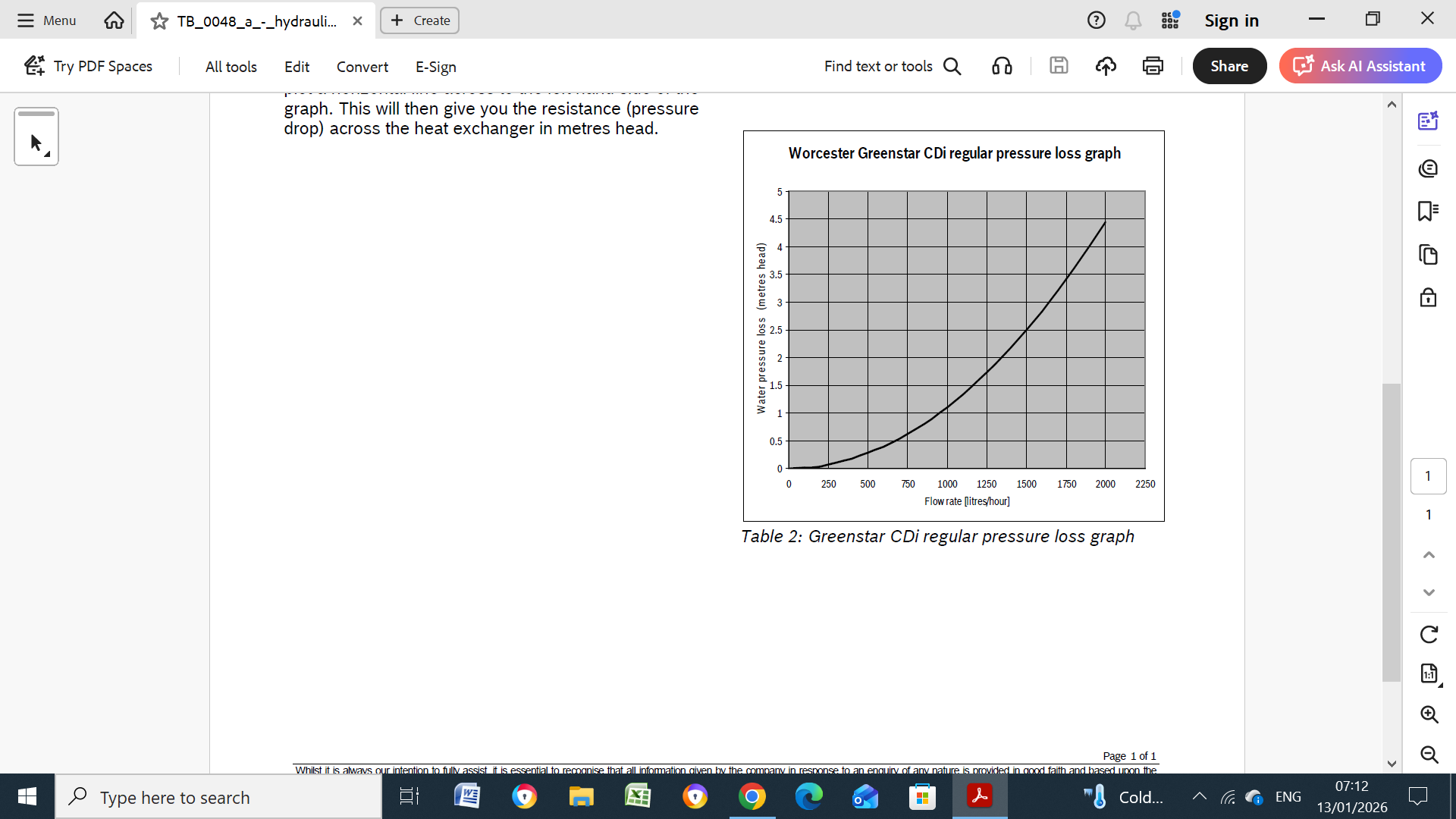

His final ‘solution’ was to set everything to maximum (boiler kW, pump pressure, etc, with modulation restricted to 80%-100% range, suggesting high resistance in the heating circuits. This, however, caused increased noise from the boiler and at radiator valves.

On the face of it, the boiler appears to be lying about the flow temperature, thus limiting its heat output to about 9kW maximum when radiators are calling for 14kW. I could give a lot more detail but it would repeat GeddeMortgage's observations.

However, I have now discovered that the external ABV is allowing flow at all times, thus returning hot flow water to the return side of the boiler. (Our ABV is fitted across flow/return pipes near the hot water cylinder but before the motorised valve, so giving a 22mm pipe circulation loop about 10m long.) So, although I have no explanation for the flow temperature display issue, I am wondering whether the continuous ABV circulation (even at 10% pump modulation) is elevating the temperature of the return water and thus limiting the amount of extra heat the boiler can then add? Alternatively, I guess this could be viewed as the ABV short-circuiting the heating circuits and depriving them of their flow? It would appear that the ABV opening pressure may be set too low - even below 100mb?

So, GeddeMortgage, you are not alone! But we still seem to be without a solution? Any further thoughts most welcome!