Dear Forum Members,

I have now completed the move. Here are a few things that were unusual or of interest:

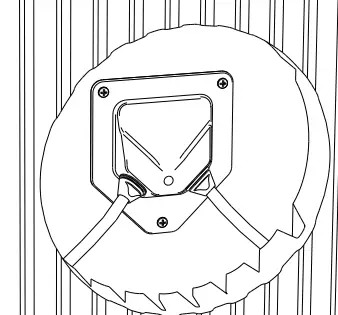

The original radiator feet supplied with the column rad were not high enough to lift the lower part of it over the skirtboard. We have this large skirtboard in our newbuild. This meant that I could not add the bottom mounting brackets, as they were catching on the skirtboard if I wanted to install them. I've used a junior hacksaw to cut off a redundant part of the bracket, to add extra support (perhaps, also redundant

).

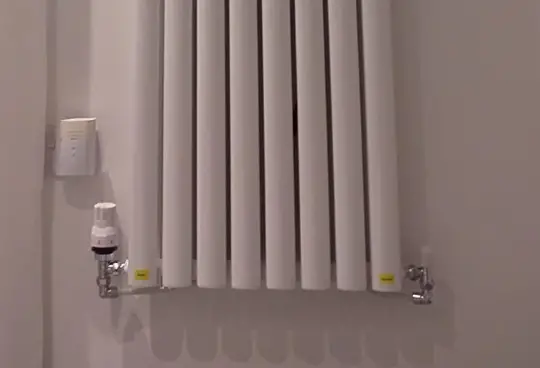

Running the actual PB pipe was super-easy. I have used a bit of spit, as advised, to help get the speedfit in place, and all worked like charm. A little access hatch was provided to allow isolating the retrofit system.

First issue was that the corner of the house didn't actually leave me any place to run the pipe, so I've just dented a little cavern in the two studs to allow some space for the pipes (and their isolation).

I know they always drop the pipes from the ceiling, but I have no idea how I would have opened the ceiling to re-run the pipe.

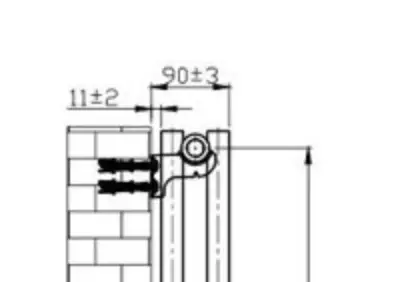

The second issue was getting the 10mm pipe to bend the way I want it to, through the face fix plate. I ended up making a loop inside the wall, to bend it the right way.

Getting through the exterior wall was a massive pain, as it had a layer of wood between the plasterboard and the TSW studs with insulation behind them. My cheap multitool has barely managed to get through it. The Japanese blade was completely ruined, and only the kit half-moon blade was able to slowly cut through it. What a tough material!

Putting the wall back together and plastering over it was horrendous, as in the exterior wall I could not rest the parts I've cut out on any studs - there was a power socket in-between, which prevented the cutout from staying in one piece. Or something like that

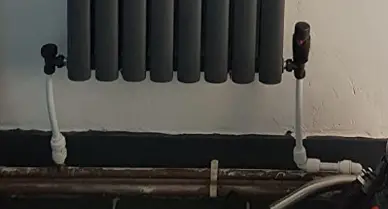

In terms of plumbing, I have re-used the same lockshields, filled the system, bled, re-inhibited via towel-rail radiator upstairs and switched on the boiler + heating.

The rad stayed cold. I tried re-balancing, but it didn't do much - all rads had their lockshields on one-quarter of a turn, and this new one had both valves open.

Eventually, I've made a contraption to get out a possible airlock: Took a 1/2 inch thread to 15mm push-fit adapter with a lengh of pipe from

screwfix.

I've switched off the boiler with the system pressurised, closed both valves in the new rad, plugged the contraption into the bleed valve (after reducing the pressure in the rad), then opened the Inlet to flush out any airlocks. Then closed the inlet and opened the out lockshield to do the same. It didn't sound like much, but upon re-pressurising the system the rad went nice and hot in a few minutes.

I didn't trust my plumbing skills, so I have made a mistake of not mending the wall before offering up the rad and connecting it. So today I had to isolate the new radiator, drain it, take it off the wall and try to mend the holes (through which cold wind was blowing in, somehow!!). Eventually I have put the rad back up, proactively flushed some air out of it, re-bled, re-pressurised and re-inhibited the system (again!).

Luckily, the heating works. The wall looks horrible though!

Is it OK to leave most of the rads in the house with the OUT lockshield only on one quarter of the turn?