Hi All

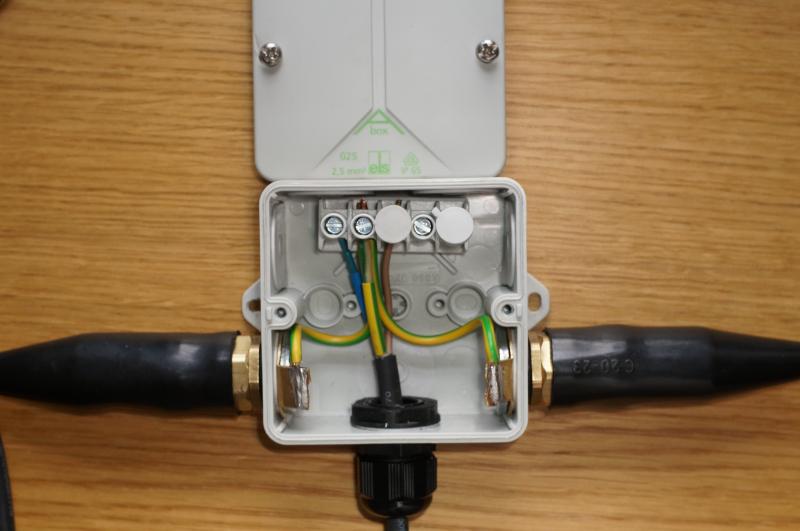

Wiring a junction box - Is this considered an acceptable method of bonding the earths? Soldered banjo, clipped short and clamped to the inside of the enclosure with the gland nut. Photo attached.

Alternatives are:

1/ Piranha / p-nut / lynx nut (expensive on bigger jobs)

2/ Clamp banjo between two nuts on inside (not enough thread)

3/ Traditional banjo on outside with screw through (ruins IP rating, possible plastic deformation over time)

4/ Use an earth clamp bar http://www.tlc-direct.co.uk/Products/WKEC308.html (only good if swa glands are on the same side, no other downside)

Problems with the photographed method - zinc plated nut may degrade over time, reducing the integrity of the bond. Can't seem to find slim brass ones easily.

Comments / opinions please - specifically, what is the PROPER method, before piranha nuts existed.

Thanks

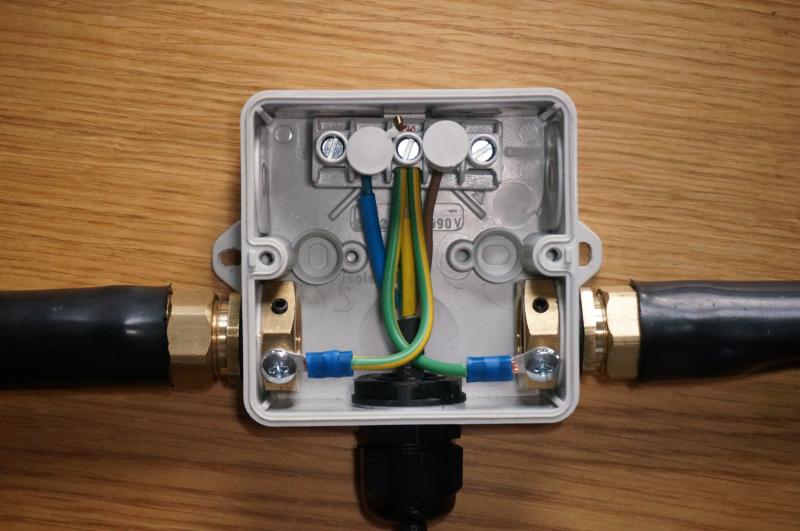

Wiring a junction box - Is this considered an acceptable method of bonding the earths? Soldered banjo, clipped short and clamped to the inside of the enclosure with the gland nut. Photo attached.

Alternatives are:

1/ Piranha / p-nut / lynx nut (expensive on bigger jobs)

2/ Clamp banjo between two nuts on inside (not enough thread)

3/ Traditional banjo on outside with screw through (ruins IP rating, possible plastic deformation over time)

4/ Use an earth clamp bar http://www.tlc-direct.co.uk/Products/WKEC308.html (only good if swa glands are on the same side, no other downside)

Problems with the photographed method - zinc plated nut may degrade over time, reducing the integrity of the bond. Can't seem to find slim brass ones easily.

Comments / opinions please - specifically, what is the PROPER method, before piranha nuts existed.

Thanks