Thanks for the comments. Whilst at Alton towers a couple of weeks ago, I noticed that all of the plastic enclosures on rides had banjos on the outside. Some where mounted on rails, which would be subject to vibration... I guess this is just the way it is. I suppose if there is an earth core too, then only one of the ends would need to be in good contact for the armour to be earthed.

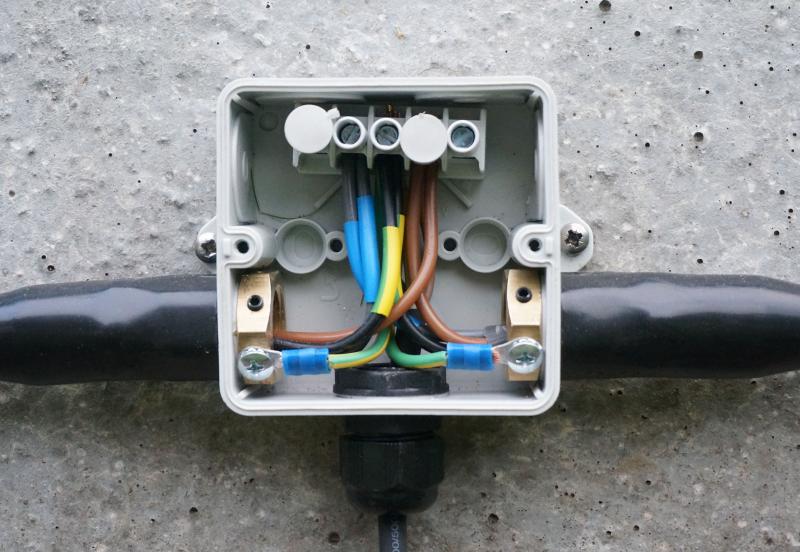

I'll post photos of a wired box in situ when I'm doing the install for newcomers benefit.

I'll post photos of a wired box in situ when I'm doing the install for newcomers benefit.