10 years ago I bought the Alpina C38 chainsaw to cut down a few trees in the garden. Since then it’s lived in the shed untouched. The other day I got it out and had a smell of the fuel of which didn’t really smell of anything.

I gave the rope a pull & it started & ran fine “WOW”

I dumped the fuel mix and replaced with new. Used it yesterday for an hour & did t miss a beat.

My question is when I unscrewed the fuel cap there was a fine spray of fuel as i unscrewed it.

Any advice about this ?

I mean none of my other tools do this.

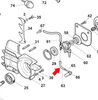

Secondly this morning there was a very small puddle of red oil below the chainsaw.

I see a tank for oil of which I assume must lubricate the chain etc so does the oil get flicked into the unit then drip down once stood or is there a leak ?

Any advice please.

Thanks.

I gave the rope a pull & it started & ran fine “WOW”

I dumped the fuel mix and replaced with new. Used it yesterday for an hour & did t miss a beat.

My question is when I unscrewed the fuel cap there was a fine spray of fuel as i unscrewed it.

Any advice about this ?

I mean none of my other tools do this.

Secondly this morning there was a very small puddle of red oil below the chainsaw.

I see a tank for oil of which I assume must lubricate the chain etc so does the oil get flicked into the unit then drip down once stood or is there a leak ?

Any advice please.

Thanks.