- Joined

- 30 Apr 2021

- Messages

- 87

- Reaction score

- 7

- Country

Dear forum members!

I am a complete novice in these matters and would greatly appreciate your help.

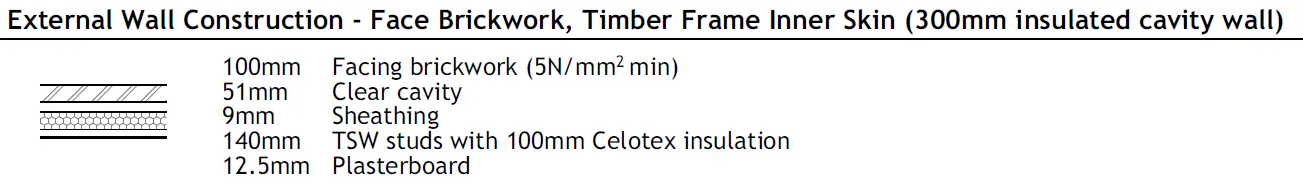

I have external wall specification for my house listed as such:

So I assume that wooden sheathing must be BEHIND the TSW studs.

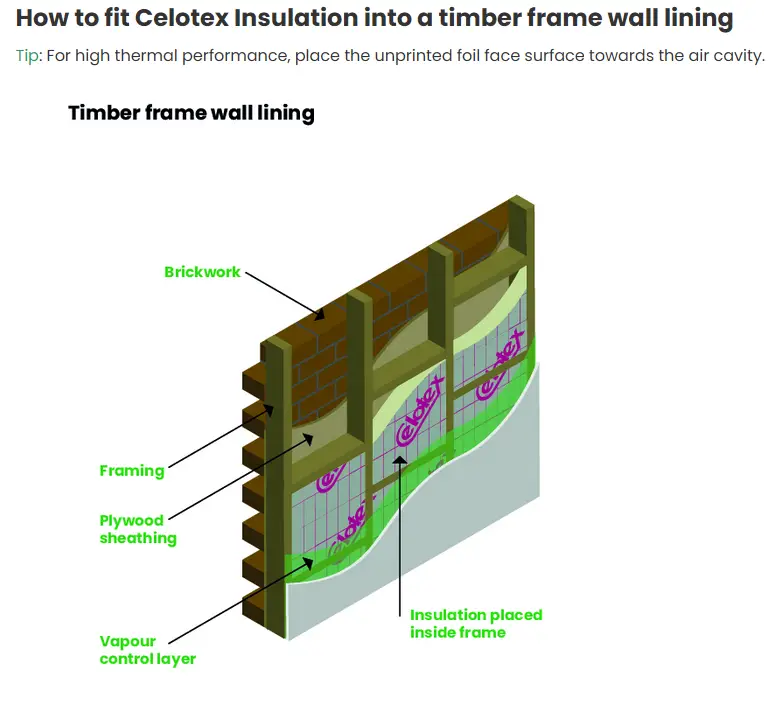

This is confirmed by the Celotex website:

However, I've just had to open up the wall and I noticed that the sheathing is right behind the plasterboard! My poor oscillating mutitool nearly broke down.

First, is this normal?

What are the side-effects of having the sheathing on the inside of the studs?

Thank you!

I am a complete novice in these matters and would greatly appreciate your help.

I have external wall specification for my house listed as such:

So I assume that wooden sheathing must be BEHIND the TSW studs.

This is confirmed by the Celotex website:

However, I've just had to open up the wall and I noticed that the sheathing is right behind the plasterboard! My poor oscillating mutitool nearly broke down.

First, is this normal?

What are the side-effects of having the sheathing on the inside of the studs?

Thank you!