Hi

I have a very specific question so please excuse the very long post. Here goes...

We've been having some work done to the house recently, the main part of which involved knocking through between the existing kitchen and an adjoining room. In terms of electrics, the work included: new lights to kitchen/diner, new lights + fan to utility room, new lights + fan to shower room, feeds to 2 ovens and an electric hob, some extensions to the downstairs mains ring (including fused spur for cooker hood) and new feed to garage for light and sockets.

I have in the past used an electrcian who came recomended by family and was very happy with his work. However, for this project, which is being project managed by our builder neighbour, the work has been done by his usual electrician, who will notify and self-certify the work.

I have lost confidence in the electrician, having pulled him up on what I feel was a negligent act and am now worried about potential unseen horrors. In particular, I am worried about the lighting cuircuit in the kitchen although my worries may be unjustified - I would appreciate your views/advice.

Originally the kitchen and the adjoining room each had two light fittings, each operated independently via two double gang switches. In the new kitchen diner, we asked for three switches: one for the kitchen side of room, one for the other and one for under cupboard lights. We wanted the triple gang switch to be at the entrance to the new room, approximately where the existing double gang switch for the adjoining room was (next to the door but moved horizontally by approx 10cm to accomodate a new cupboard). Each side of the room has 6 spotlights, the cables are installed for the under cupboard lights which I am going to connect up myself.

When the first fix was done, the electrician used a junction box to connect to the existing circuit. This is now above a false ceiling and I understand may not be compliant since it is not 'accessible'. However, in the spirit of picking my battles, since I see this as a convenience issue rather than a safety issue (happy to be corrected) I let this one go.

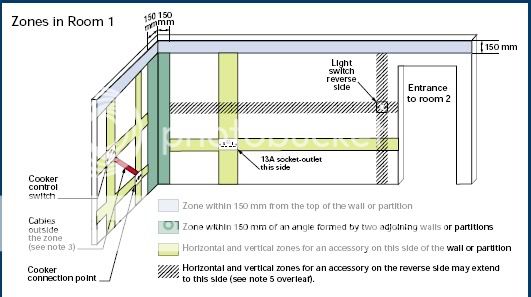

He also used the existing cables which ran down to the double gang switch. However, it seems that these run outside of the safe zones - they run vertically upwards to the height of the door and then, once above the door, they angle at approx 45 degrees and run to the corner of the room. At the time, I asked if that was acceptible and he said that it was fine since it was an existing circuit. (I don't know if it changes matters but he did move the vertical section of the cables to the right by 10cm - would that still make it an 'existing' cable?). Although I felt that the electrician had been (typically) lazy by not running a couple of metres of new T+E (of course the new cable for the under cupboard lights had been run down from the ceiling - why didn't he just run new cable for the other two switches!? ) the cabling was done and plastered over by the time I got home from work.

) the cabling was done and plastered over by the time I got home from work.

I have only just reached the stage of attaching the under cupboard lights and therefore only recently taken the face plate off the triple gang switch. I found that the two (old) feeds for the ceiling lights comprise: one cable with three cores (red, red + yellow/green) and one single core (red, sheathed in black); he has linked the COMS for the two switches. I'm now worried about this arrangement that it may not be compliant/safe. I'm not sure where this single core cable comes from and whether or not there is a shared neutral/live; I'm not sure if it is acceptable given that it runs outside of the safe zones (is it an existing circuit when you completely replace all of the light fittings and most of the cable but keep a dodgy 2m of old cable running to a switch?).

The electrician has now completed the work but still needs to give us the certificate and we still owe him for part of the work.

I'm considering asking another electrician to look over the work and, if he feels it necessary, to make it compliant. If it is not compliant I would then subtract what I pay the new electrician from what I owe the original guy. Does that seem reasonable?

If you need any more info, please let me know.

Thanks in advance (and sorry again for the length of the post).

I have a very specific question so please excuse the very long post. Here goes...

We've been having some work done to the house recently, the main part of which involved knocking through between the existing kitchen and an adjoining room. In terms of electrics, the work included: new lights to kitchen/diner, new lights + fan to utility room, new lights + fan to shower room, feeds to 2 ovens and an electric hob, some extensions to the downstairs mains ring (including fused spur for cooker hood) and new feed to garage for light and sockets.

I have in the past used an electrcian who came recomended by family and was very happy with his work. However, for this project, which is being project managed by our builder neighbour, the work has been done by his usual electrician, who will notify and self-certify the work.

I have lost confidence in the electrician, having pulled him up on what I feel was a negligent act and am now worried about potential unseen horrors. In particular, I am worried about the lighting cuircuit in the kitchen although my worries may be unjustified - I would appreciate your views/advice.

Originally the kitchen and the adjoining room each had two light fittings, each operated independently via two double gang switches. In the new kitchen diner, we asked for three switches: one for the kitchen side of room, one for the other and one for under cupboard lights. We wanted the triple gang switch to be at the entrance to the new room, approximately where the existing double gang switch for the adjoining room was (next to the door but moved horizontally by approx 10cm to accomodate a new cupboard). Each side of the room has 6 spotlights, the cables are installed for the under cupboard lights which I am going to connect up myself.

When the first fix was done, the electrician used a junction box to connect to the existing circuit. This is now above a false ceiling and I understand may not be compliant since it is not 'accessible'. However, in the spirit of picking my battles, since I see this as a convenience issue rather than a safety issue (happy to be corrected) I let this one go.

He also used the existing cables which ran down to the double gang switch. However, it seems that these run outside of the safe zones - they run vertically upwards to the height of the door and then, once above the door, they angle at approx 45 degrees and run to the corner of the room. At the time, I asked if that was acceptible and he said that it was fine since it was an existing circuit. (I don't know if it changes matters but he did move the vertical section of the cables to the right by 10cm - would that still make it an 'existing' cable?). Although I felt that the electrician had been (typically) lazy by not running a couple of metres of new T+E (of course the new cable for the under cupboard lights had been run down from the ceiling - why didn't he just run new cable for the other two switches!?

I have only just reached the stage of attaching the under cupboard lights and therefore only recently taken the face plate off the triple gang switch. I found that the two (old) feeds for the ceiling lights comprise: one cable with three cores (red, red + yellow/green) and one single core (red, sheathed in black); he has linked the COMS for the two switches. I'm now worried about this arrangement that it may not be compliant/safe. I'm not sure where this single core cable comes from and whether or not there is a shared neutral/live; I'm not sure if it is acceptable given that it runs outside of the safe zones (is it an existing circuit when you completely replace all of the light fittings and most of the cable but keep a dodgy 2m of old cable running to a switch?).

The electrician has now completed the work but still needs to give us the certificate and we still owe him for part of the work.

I'm considering asking another electrician to look over the work and, if he feels it necessary, to make it compliant. If it is not compliant I would then subtract what I pay the new electrician from what I owe the original guy. Does that seem reasonable?

If you need any more info, please let me know.

Thanks in advance (and sorry again for the length of the post).