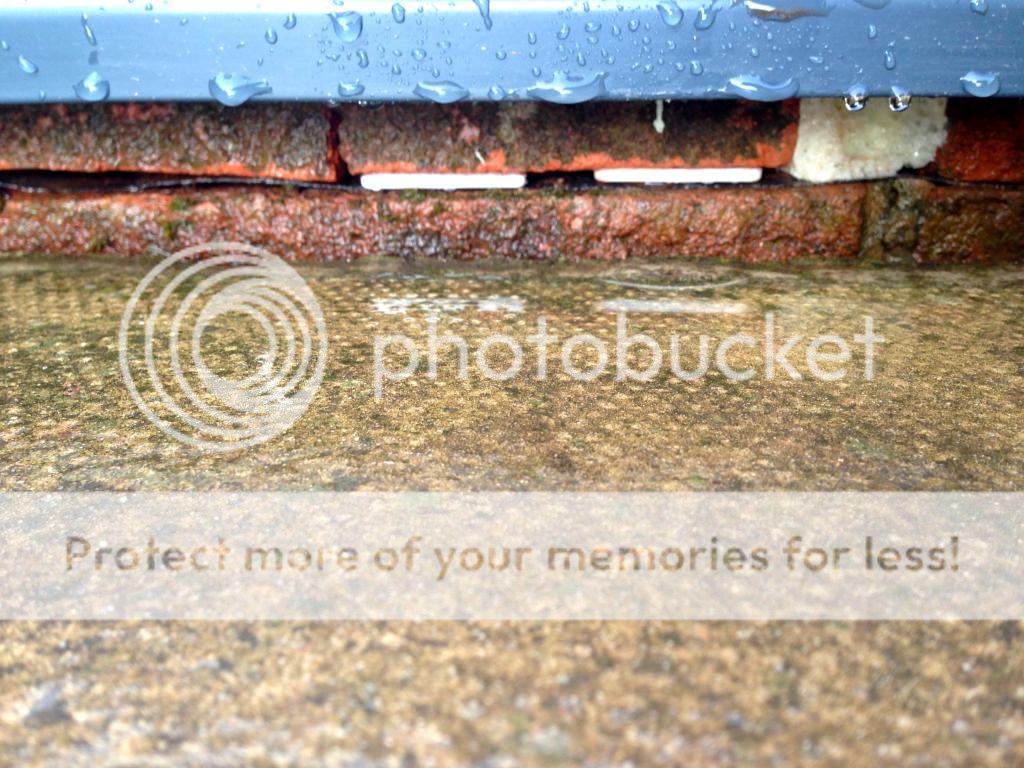

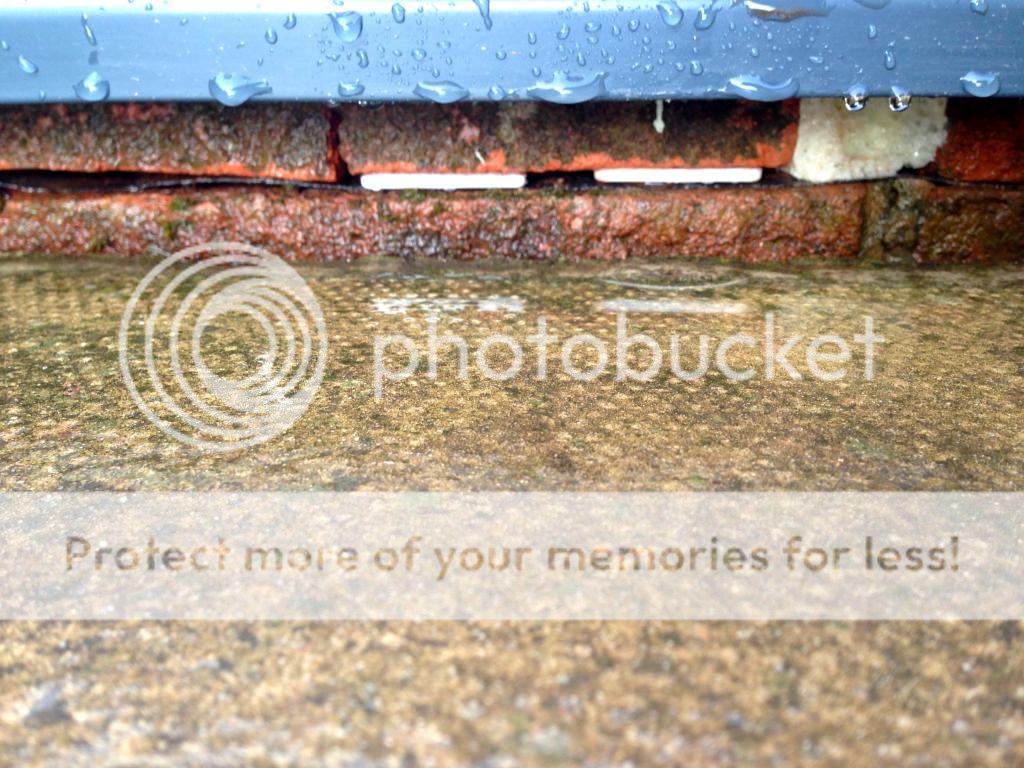

Ive just had a set of new aluminium bifold doors fitted and I've only just noticed that the brickwork/mortar underneath the doors look extremely poor.

They had to cut a row of bricks in order to lower the door threshold, but it looks like they've used expanding foam and spacers instead of mortar. Even one of the cut down bricks has broken into two. Surely this hasn't been done correctly?

I realise I should have inspected their work before signing it off, but i was concentrating more on checking the door operation.

They had to cut a row of bricks in order to lower the door threshold, but it looks like they've used expanding foam and spacers instead of mortar. Even one of the cut down bricks has broken into two. Surely this hasn't been done correctly?

I realise I should have inspected their work before signing it off, but i was concentrating more on checking the door operation.