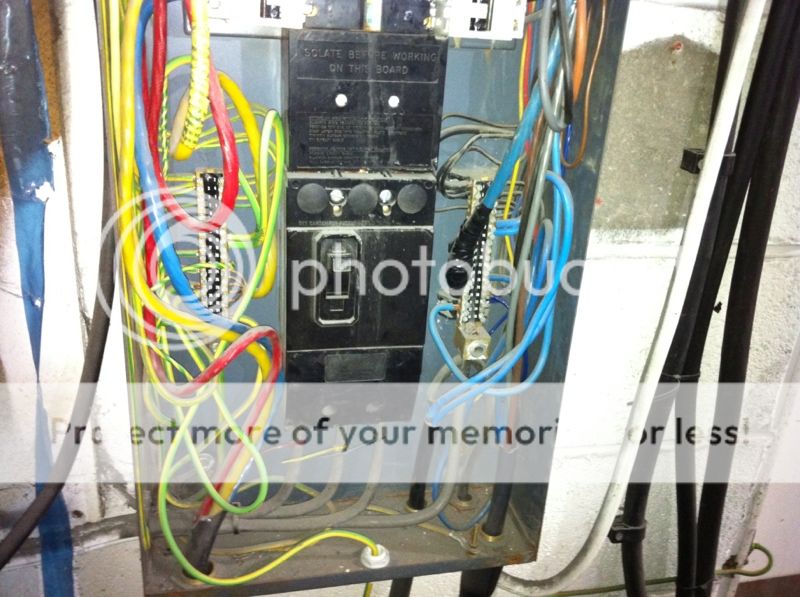

Came across a very bizarre setup this week.

This is a 50A TP&N supply to a submains in a factory.

The 35mm² 3 core R-Y-B SWA on the left of the picture supplies the submain with it's lives, and 16.0mm² 2 core SWA supplies the neutral.

Here's the other end.

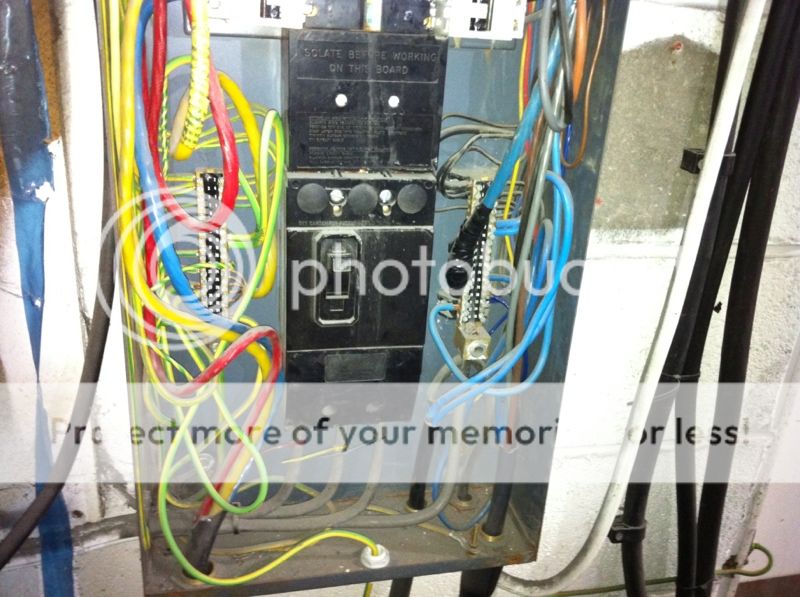

There are no slots cut between the glands, and both DBs are steel.

The submains supplies mainly TP machinery, and the neutral current is small, only 4 or 5 amps, but it's still not right.

How would you word this on the repord, how would you code it, and how would you put it right?

This is a 50A TP&N supply to a submains in a factory.

The 35mm² 3 core R-Y-B SWA on the left of the picture supplies the submain with it's lives, and 16.0mm² 2 core SWA supplies the neutral.

Here's the other end.

There are no slots cut between the glands, and both DBs are steel.

The submains supplies mainly TP machinery, and the neutral current is small, only 4 or 5 amps, but it's still not right.

How would you word this on the repord, how would you code it, and how would you put it right?