Hi all.

I am going to replace my rotten porch with a new one but I also want to extend the porch canopy across the front of my garage.

The garage is integral and was built as part of an extension years ago.

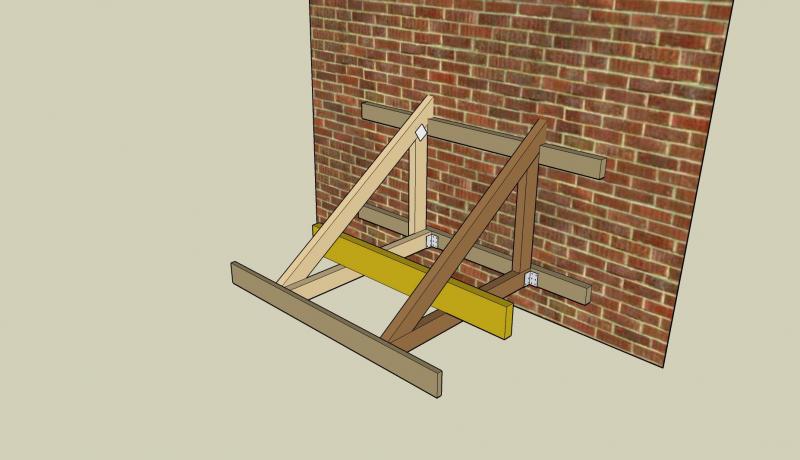

My question is: what is the best method of constructing the canopy and fixings, ie, steel angle brackets (upside down gallows brackets) or brackets made with 3 x 2 wood. The wall is made from 10" breeze block with a sand and cement render.

I have been looking at resin ancors as fixings but am not sure what size would be needed.

The canopy will be unsupported, apart from the porch at one end, will be approx 6m across and tiled with red roofing tiles, not the very heavy concrete ones, but still heavy enough.

Any help advice appreciated.

Paul

I am going to replace my rotten porch with a new one but I also want to extend the porch canopy across the front of my garage.

The garage is integral and was built as part of an extension years ago.

My question is: what is the best method of constructing the canopy and fixings, ie, steel angle brackets (upside down gallows brackets) or brackets made with 3 x 2 wood. The wall is made from 10" breeze block with a sand and cement render.

I have been looking at resin ancors as fixings but am not sure what size would be needed.

The canopy will be unsupported, apart from the porch at one end, will be approx 6m across and tiled with red roofing tiles, not the very heavy concrete ones, but still heavy enough.

Any help advice appreciated.

Paul