delete

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

House Re-Wire Plan please critique

- Thread starter mattysmithuk

- Start date

I'm sorry where above does it say anything about domestic situations.With copper prices expected to triple over the next few years watch out for the return to vogue of RFC

The ring final circuit has always used more copper than necessary. The original assumptions which brought about its introduction were quite simply incorrect.

When you talk about original assumptions being incorrect, I take it you are talking about the history of the ring viz.. The ring main came about because Britain had to embark on a massive rebuilding programme following World War II. There was an acute shortage of copper, and it was necessary to devise a scheme that used less copper than would normally be the case. The scheme was specified to use 13 A fused socket outlets, and several designs for the plugs and sockets appeared. Only the square pin (BS 1363) system survives, but the round pin Dorman & Smith system was still in use in many locations well into the 1980s, and is still occasionally seen today. This latter plug had the distinctive feature that the fuse was also the live pin and unscrewed from the plug body.

The ring circuit was devised during a time of copper shortage to allow two 3 kW heaters to be used in any two locations and to allow some power to small appliances, and to keep total copper use low. It has stayed the most common circuit configuration in the UK, although the 20 A radial (essentially breaking each ring in half and putting the halves on a separate breaker) is becoming more common. Splitting a ring into two 20 A radials can be a useful technique where one leg of the ring is damaged and cannot easily be replaced.

Another advantage of ring circuits was an economy of cable and labour, as one could connect a cable between two existing 15 A radially wired sockets to make one 30 A ring, then adding as many sockets as were desired. This was an important consideration in the austerity of the 1940s. This would leave the ring supplied by two 15 A fuses, which worked well enough in practice, even if unconventional (Source wikipedia)

But for socket outlets in a domestic installation, you will always use more copper if you install rings. (I never mentioned and would never use 4 sq mm, which appears to be the basis for your thesis.)

Whether or not you use 4mm T&E is immaterial, I have simply challenged your broad statement, outlined above, and demonstrated that there are circumstances where that statement may be correct but also there are circumstances where that statement is incorrect.

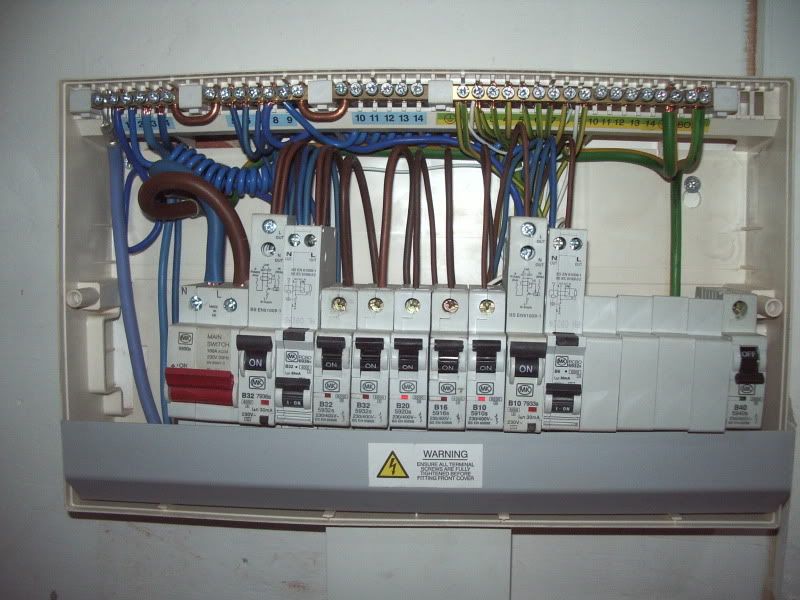

This is a house I rewired to the 17th edition.

From the main switch:

(1)Upstairs ring final circuit. (13 points in 3 bedrooms, landing and loft)

(2)Downstairs ring final circuit. (12 points in hall, lounge and kitchen diner)

(3)6.0mm² radial for hob

(4)4.0mm² radial to kitchen gridswitch for washer, dryer, dishwasher.

(5)2.5mm² radial for oven and extractor hood.

(6)2.5mm² radial for fridge freezer

(7)Boiler

(8)Upstairs lights

(9)Downstairs lights

can i ask a few questions?

i guess those large items are RCBO's? and they take the live and neutral wire from the circuit, also why are slightly different?

i would of thought a 32a on a 4.0mm2 was very close to the capacity of the cable, as its around 32amps anyways.

also why are the 2.5mm2 T&E for the oven and fridge, are protected by a 20a and a 16a MCB on different circuits.

im not picking holes in your work, im just a keen learner.

thanks.

Whether or not you use 4mm T&E is immaterial, I have simply challenged your broad statement, outlined above, and demonstrated that there are circumstances where that statement may be correct but also there are circumstances where that statement is incorrect.

I don't think you have demonstrated anything of the sort.

As for the 'domestic' reference, the ring final circuit was devised expressly for the use of domestic socket-outlets. And as the thread is about a house rewire, my assertion still stands; to use rings will require more cable for the same outcome.

(To echo something that is also regularly aired here, from the same Wikepedia page: "It is also becoming very apparent that a majority of UK electricians are unfamiliar with the test requirements and, as a result, most ring circuits are not adequately tested, either at first installation or subsequently during the infrequent periodic inspections.")

For a radial sub-main, or to supply fixed equipment, then whatever cable size most economically does an effective job. But to directly supply sockets, no.Would you not consider using 4.00mm on radials for supplying circuits to uttilities and the garage work shop, bearing in mind the protective device rating will offer you more current?

We will just have to agree to disgree then.As for the 'domestic' reference, the ring final circuit was devised expressly for the use of domestic socket-outlets. And as the thread is about a house rewire, my assertion still stands; to use rings will require more cable for the same outcome.

(To echo something that is also regularly aired here, from the same Wikepedia page: "It is also becoming very apparent that a majority of UK electricians are unfamiliar with the test requirements and, as a result, most ring circuits are not adequately tested, either at first installation or subsequently during the infrequent periodic inspections.")

Which just goes to highlight the incompetence on those people allegedly teaching and testing students.

Okay. Happy with that!We will just have to agree to disgree then.

Yes, indeed. The general standard is disappointing.Which just goes to highlight the incompetence on those people allegedly teaching and testing students.

See. That's two things we do agree on!

So you would never use an A2 type circuit on socket-outlets then?For a radial sub-main, or to supply fixed equipment, then whatever cable size most economically does an effective job. But to directly supply sockets, no.Would you not consider using 4.00mm on radials for supplying circuits to uttilities and the garage work shop, bearing in mind the protective device rating will offer you more current?

can i ask a few questions?

Of course

i guess those large items are RCBO's? and they take the live and neutral wire from the circuit, also why are slightly different?

Correct. An RCBO is a circuit breaker and an RCD combined into one unit. It monitors the current leaving on the live wire(s), and if the current returning on the neutral is the same, all is well. If there is 30mA more leavign on the live than is returning on the neutral, this means there is some curremt leaking to earth, and the device will trip.

This is why the circuit neutral is connected to the device, and then a flylead from the RCBO to the neutral bar.

They are different as MK changed the design. Part of the house was rewired, and then the rest done about 8 months later, which was long enough for them to change

i would of thought a 32a on a 4.0mm2 was very close to the capacity of the cable, as its around 32amps anyways.

4.0mm² installed to reference method C has a current carrying capacity of 37A which is well over the breaker rating.

also why are the 2.5mm2 T&E for the oven and fridge, are protected by a 20a and a 16a MCB on different circuits.

There's no real reason actually. Both circuits could run at 20A if needed. I just put a 20A circuit breaker to supply the oven as it allows a little more capacity for larger oven in future.

The fridge circuit supplies one single socket, so it will never be loded above 13A, so a 16A circuit breaker was the most apropriate choice.

im not picking holes in your work, im just a keen learner.

thanks.

No problems.

i would of thought a 32a on a 4.0mm2 was very close to the capacity of the cable, as its around 32amps anyways.

4.0mm² installed to reference method C has a current carrying capacity of 37A which is well over the breaker rating.

thanks very much for that.

can i ask what 'reference method c' is? and how you found out the cable capacity.

thanks.

Method C is clipped ditect etc, all info is in the BRB, get a copy, it makes for good bedtime reading.

Method C is clipped ditect etc, all info is in the BRB, get a copy, it makes for good bedtime reading.

BRB?

Sorry mate Big Red Book, BS7671 wiring regs

The on site guide is substantially cheaper and contains most of what would be required for a domestic installation.

http://www.amazon.co.uk/IEE-site-Guide-7671-Regulations/dp/0863418546/

http://www.amazon.co.uk/IEE-site-Guide-7671-Regulations/dp/0863418546/

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 1

- Views

- 889

- Replies

- 81

- Views

- 9K