- Joined

- 16 Jan 2009

- Messages

- 119

- Reaction score

- 0

- Country

This is my first post hear so first I would like to say hi

I have 2 Float switches that operate a ‘pump in pump’ for a mixer tank on a 12V DC circuit.

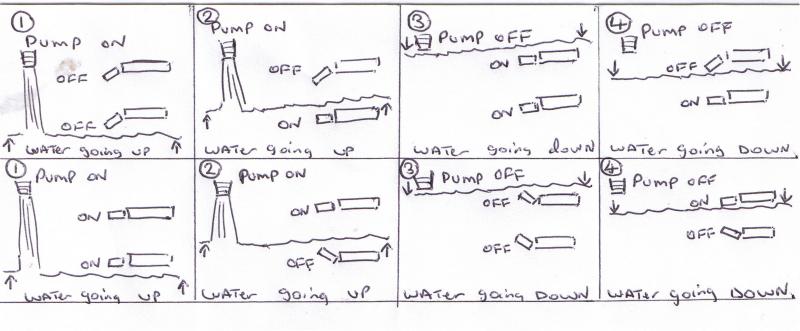

The Lower float switch turns the pump on and the upper float switch turns the pump off as can be seen in the hand draw diagram attached

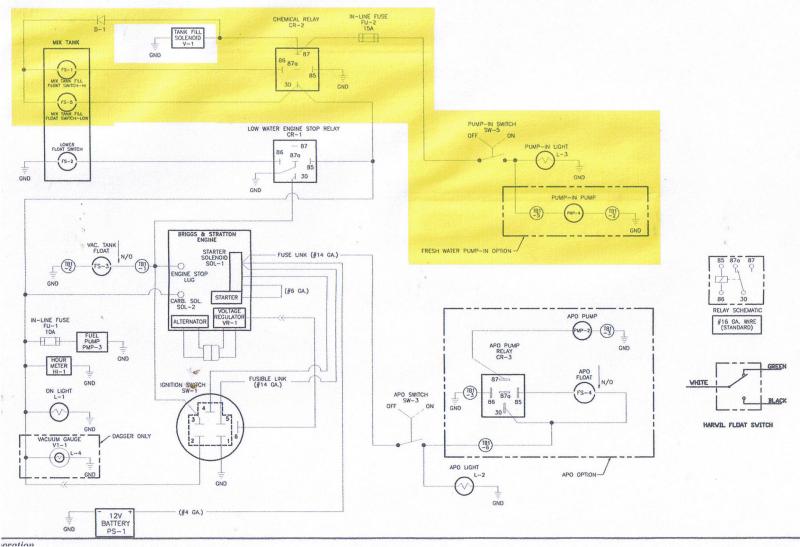

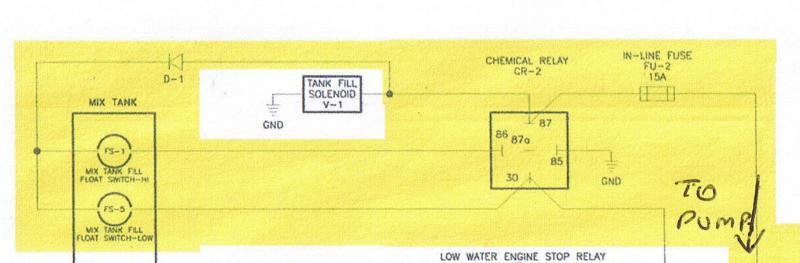

The problem is the float switches will only handle about 0.5 of an AMP and the pump has a load of 15 Amps; so they need to go through a relay which can be seen in the wiring schematic highlighted in yellow attached.

I have wired this up as seen in the schematic swapping the pump for a light bulb and the bottom sequence show in the hand drawn diagram works

But when I use the pump, the bottom float switch welds/fuses together and the pump will not turn off

Dose anyone know how to fix this problem

PS. There is no ‘Tank fill solenoid’ or ‘diode’ between FS-1 (upper float switch) and terminal 87 on the relay; as can be seen in the schematic which is not high lighted in yellow

Thanks

James

I have 2 Float switches that operate a ‘pump in pump’ for a mixer tank on a 12V DC circuit.

The Lower float switch turns the pump on and the upper float switch turns the pump off as can be seen in the hand draw diagram attached

The problem is the float switches will only handle about 0.5 of an AMP and the pump has a load of 15 Amps; so they need to go through a relay which can be seen in the wiring schematic highlighted in yellow attached.

I have wired this up as seen in the schematic swapping the pump for a light bulb and the bottom sequence show in the hand drawn diagram works

But when I use the pump, the bottom float switch welds/fuses together and the pump will not turn off

Dose anyone know how to fix this problem

PS. There is no ‘Tank fill solenoid’ or ‘diode’ between FS-1 (upper float switch) and terminal 87 on the relay; as can be seen in the schematic which is not high lighted in yellow

Thanks

James