@D_Hailsham:

Pipe 22mm and quite long pipes; but boiler now range rated at 18 kW so that should be ok I guess. One more question to the person that put this oversized boiler there...!

Boiler says VU GB 376/5-5 R1. Manual is 0020116700_02 GBIE 062012. Serial number indicates 2012 (xx12xxxxxx)

This manual does not have the graphs but it does mention different flow rates for different types of boiler; yes that is the data from the list. That would the flow required at full power and 20 degrees differential (numbers concur with my math). I think I was wrong assuming this is the minimum allowed flow for the pump...

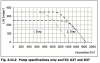

The previous model had documentation with a graph for the pump:

(True, older model, but I have a suspicion it's still the same pump and abv, so for the sake of argument, let's assume it is correct?)

So the question basically boils down to "How can I get this boiler to pump around only about 600-700 litres per hour and still keep that bypass closed??"

Restricting flow through radiators would move the flow/lift point on the above chart to the left and up, correct?

Until the ABV kicks in; I assume that is where the flat parts at 350, 250 and 175 mbar are. (That would correspond to min, default and max settings for ABV as in the manual).

Currently pump is in lowest settings (on auto and power has been range rated to 18kw). I think that's the grey line .-.

I've calculated flow through boiler by range rating it at several limits of kW's and checking what temperature differential is reported (d41-d40), ie. 12kw gives me 8 degrees; 15kW gave me 11 degrees, 22 kW gave 16 degrees. That translates to at or around 1200 litres/hour, give or take a few. (degrees are rounded to the nearest so there's some error here).

(This all with pump at low setting and ABV max at 350 mbar).

Assuming the chart is correct and I read it right this shouldn't be the case with the ABV at 350 mbar?

So, why? Blockage in the pipes somewhere so the pressure is way higher? Muck in pipes or bypass? Bypass spring broken and always open? Or am I reading the chart wrong?

Thanks again for all help in getting me to understand this system!

Would really want to be certain what's up before forking out money on WC and finding out the system was full of debris or the boiler is just way too big...

Waldo